SASCHA GREILINGER

INDUSTRIAL DESIGN STUDENT

DEUTSCH | ENGLISH

REDESIGN HAND MIXER

4th Semester | Concept And Construction

Pair Work

Pair Work

In our third semester, we did a large research about hand mixers, following the design tools of the Coburger Designpilot. After that, we reached the phase of ideation and design draft based on our insights.

A well known and wide spread kitchen utility should beredesigned and improved - in function, handling and look.

Results of the research should be considered as well as aspects of production.

A well known and wide spread kitchen utility should be

Results of the research should be considered as well as aspects of production.

CONCEPT

For me and my team partner it was very important to develop a

We got inspired by

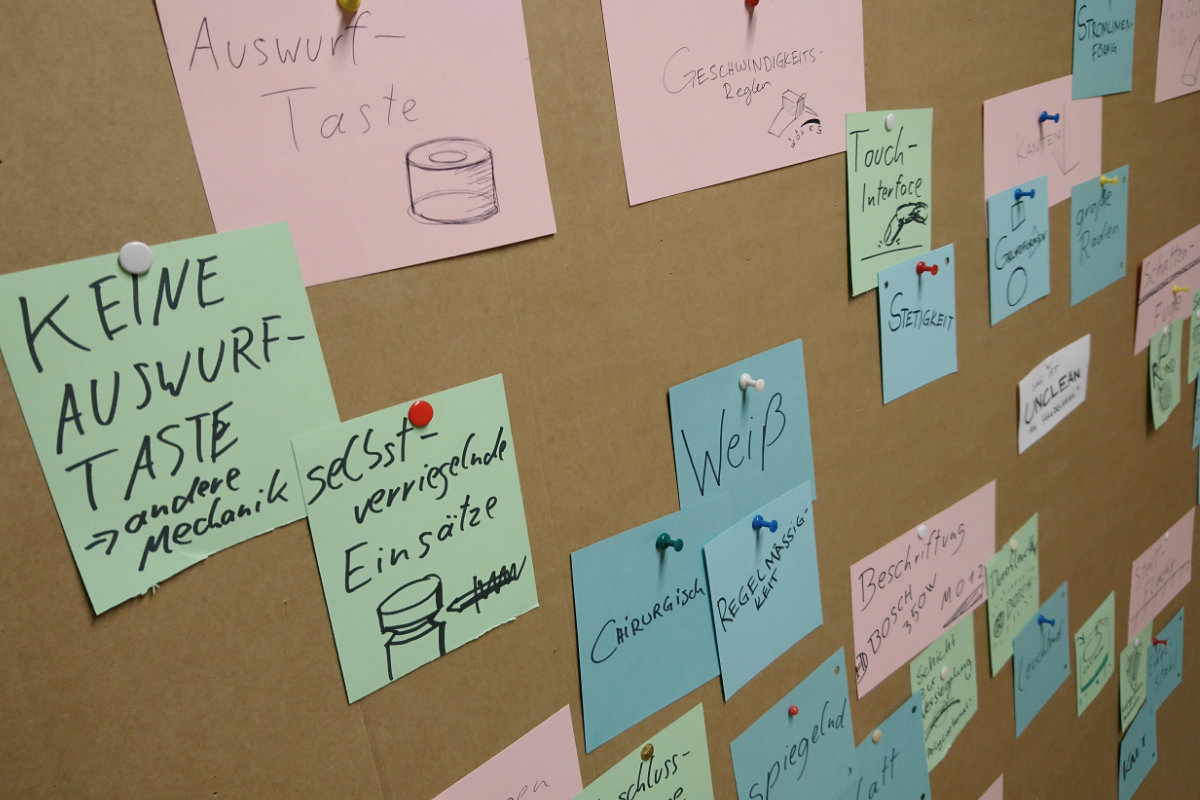

As an result of our workshop, we specify aspects for a clean design of a kitchen device. For each aspect we collect practical solutions to solve the hygienic issues.

This basic form is cutted by an elastomer band , that joins both housing shells watertight. It's main intention is to be a central element in the look of the device but also to be a highly integrated part.

The housing consists of a rather unusual material in the kitchen world:Magnesium . It's lightweight, inherently stable and got good thermal properties for passive cooling.

Following the principle of an electric shaver, the hand mixer should be awatertight, cordless operated device with the option of mains operation by the use of an adaptor.

The housing consists of a rather unusual material in the kitchen world:

Following the principle of an electric shaver, the hand mixer should be a

THE FUNCTIONAL BAND

The elastomer band is the

Reliable sealing of the housing shells

Inheritation of the interface, close to the user

Ergonomic functions

Connecting the plug of the adaptor

Covering of mounting parts

Providing re-opening of the housing

Breaking of the shape with colour as a formal element

Labeling (brand, name, rating plate)

BENEFITS

Interfaces to the outside are only created through the band. Parts surrounded by the elastomer are completely protected from humidity

One high integrated part replaces many separate components

Only few casting tools needed

The basic shape of the housing is only seperated by the band without any gaps or pits. There are only additive applied feets and the outlet of the accessoire coupler.

UX DESIGN MOCKUP

To test the usability of our developed

It comes with motors, a button, a capacitive sensor, a RGB-LED and a battery pack. Everything is mounted on two lasercutted plywood boards and controlled by an

Activating, speed control and safety functions could be shown directly during our user tests and presentations.

MODEL

THE WEBSITE. HAND-CODED NOT WORD-PRESSED. NO SCRIPTS, NO COOKIES, NO DATA COLLECTING - PURE HTML